Before this section starts I will be referring to Cat-(5-8) cable as Cat-5 for simplicity as the rest use the same wiring standard, just different shielding, twisted pair, and conductor width methods and lengths.

When creating/splicing Cat-5 cable (Catagory 5) also known as Ethernet Cable there is a few tools you will need to start. Firstly, a RJ45 crimper and RJ45 connectors. Make sure to buy the corresponding RJ45 to Cat-x connector as the width of the conductors varies from version to version (learned the hard way). Once you have those, optionally you can buy a cable tester to make sure you wired everything the correct way. On top of that, you will obviously need the cable itself with no end.

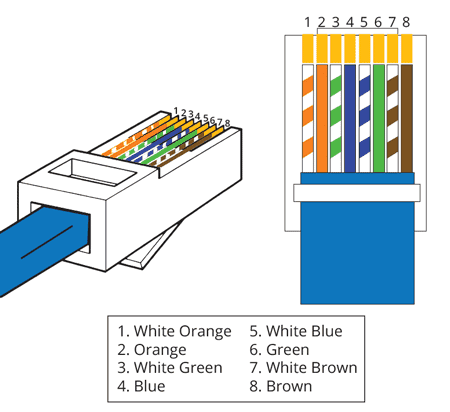

You first start with stripping all the shielding off the cable to prepare it for the connector. You start this by either carefully cutting the plastic shielding with a razor blade or some crimpers come with a slot to put the cable into and it has a blade to cut it to the exact width. Some Cat-5 cable has a thin strand of silk you can pull to rip off more shielding or you could. You want to pull off ~1 inch or 2. Once you tear off the shielding you prep the wires to go into the RJ45 connector. Below is a pin-out diagram for ethernet cable. It’s important that you stick to the standard T-568B as this standard is best suited for low cross-talk and high data speeds. Some other standards may be for lower speeds or even for audio which many people don’t know you can use Cat-5 for audio, which I’ve done many times and it works great.

Now, when it comes to unraveling Cat-5 there is a great trick I found years ago linked here. Once all wires are straight and unwraveled you push the corresponding color into the corresponding slot. One thing to note is some RJ-45 connectors are through-hole and closed ends. What this means is when you push the cable through the slot, the through-hole allows you to push the whole conductor through the end of the cable. Once all all conductors are through the hole, you snip the ends, or some cable crimpers when it comes time to crimp, will automatically cut the ends for you. Closed ends are what they say they are; they stop the conductor at the end of the connector. I would recommend using though-hole as it will save you from pulling out your hair and trying to make sure already-put-in conductors don’t come out.

Lastly, when all conductors are aligned in their correct holes, you put the cable crimper around the connector and squeeze extra firmly. You might hear it click and that’s an indication the crimp is complete. After that, you repeat these steps at the other end. Additionally, if you have a cable tester, use it to check your connections. Otherwise, plug in the cable to whatever you want to plug into and test your connection.

When I created my first cables I tested them using iperf, which is a tool to test bandwidth. If everything checks out and your connection is solid and can carry data at the desired speeds, you just created your first cable. Congratulations!

If you want a good video to visually see how to do it for the first time you can check this one out here.